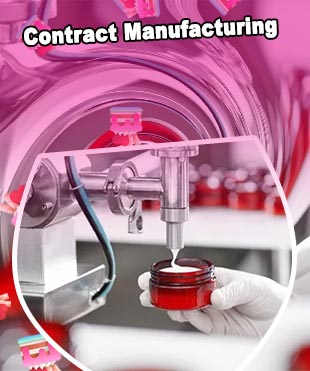

Personal care contract manufacturing companies

When looking for personal care contract manufacturing companies, it is important to consider various factors such as capabilities, quality control, and pricing. To help you make an informed decision, we have compiled a list of four articles that provide valuable insights into this topic. These articles cover a range of aspects related to personal care contract manufacturing companies, including tips for selecting the right partner, the latest trends in the industry, and key considerations to keep in mind during the selection process.

Top 10 Tips for Choosing the Right Personal Care Contract Manufacturing Company

When it comes to selecting the perfect personal care contract manufacturing company, there are several key factors to consider in order to make an informed decision. One of the most important aspects is to thoroughly research the reputation and track record of the company. Look for testimonials and reviews from previous clients to get an idea of the quality of their products and services.

Additionally, it is crucial to ensure that the company has the necessary certifications and compliances in place to guarantee the safety and quality of their products. This includes certifications such as FDA registration and Good Manufacturing Practices (GMP) compliance. By choosing a company that meets these standards, you can have peace of mind knowing that your products are in good hands.

Another tip is to consider the company's production capacity and capabilities to ensure that they can meet your specific manufacturing needs. It is also important to discuss pricing and payment terms upfront to avoid any surprises down the line.

In conclusion, selecting the right personal care contract manufacturing company requires careful consideration and research. By following these tips, you can make an informed decision that will benefit your business in the long run.

Emerging Trends in Personal Care Contract Manufacturing

In the United States, the personal care contract manufacturing industry is experiencing significant growth and transformation, driven by emerging trends that are shaping the market. One key trend that is gaining momentum is the increasing demand for natural and organic products. Consumers are becoming more conscious about the ingredients in their personal care products, leading to a rise in the production of natural and organic formulations. Contract manufacturers are responding to this trend by developing capabilities to produce these products efficiently and at scale.

Another important trend in the personal care contract manufacturing industry is the growing focus on sustainable and eco-friendly practices. Consumers are increasingly looking for products that are not only good for their skin, but also for the environment. Contract manufacturers are incorporating sustainable practices into their operations, such as using renewable energy sources and reducing waste.

Furthermore, technology is playing a significant role in shaping the future of personal care contract manufacturing. Advancements in automation, artificial intelligence, and data analytics are enabling manufacturers to streamline their processes, improve product quality, and increase efficiency.

Overall, these emerging trends are reshaping the personal care contract manufacturing industry in the United States. For beauty brands and retailers looking to stay competitive in the market, staying abreast of these trends and partnering with contract manufacturers that are at the forefront of innovation is crucial. By embracing natural and organic

Quality Control Practices in Personal Care Contract Manufacturing

When it comes to personal care products, ensuring quality control practices are in place is essential to guaranteeing the safety and effectiveness of the items we use on our bodies daily. In the United States, consumers are increasingly mindful of the ingredients in their personal care products, making it crucial for contract manufacturers to uphold stringent quality control measures.

One key aspect of quality control practices in personal care contract manufacturing is ingredient sourcing. Contract manufacturers must carefully vet their suppliers to ensure they are providing high-quality, safe ingredients for use in products. This includes conducting thorough research on the source of the ingredients, as well as testing for purity and potency.

In addition to ingredient sourcing, product testing is another critical component of quality control practices. Contract manufacturers should conduct rigorous testing throughout the production process to ensure products meet safety and efficacy standards. This includes testing for stability, microbial contamination, and product performance.

Furthermore, maintaining a clean and sanitary production environment is vital for upholding quality control practices. Contract manufacturers should follow Good Manufacturing Practices (GMP) to ensure their facilities are up to standard and free from contaminants that could compromise the quality of the products being produced.

Overall, quality control practices in personal care contract manufacturing play a crucial role in delivering safe and effective products to consumers. By prioritizing ingredient sourcing, product testing

Key Considerations for Selecting a Personal Care Contract Manufacturing Partner

When it comes to outsourcing personal care product manufacturing, choosing the right partner is crucial for success. A reputable contract manufacturing partner can help streamline production processes, ensure product quality, and meet regulatory requirements.

One key consideration when selecting a personal care contract manufacturing partner is their expertise in the industry. It is essential to work with a partner who has extensive experience in formulating and producing personal care products. This expertise can make a significant difference in the quality and consistency of the products being manufactured.

Another important factor to consider is the partner's manufacturing capabilities. A partner with state-of-the-art facilities and equipment can offer efficiency and scalability, allowing for quicker turnaround times and the ability to meet increased production demands.

Additionally, it is essential to evaluate the partner's commitment to quality control and regulatory compliance. A reliable partner will have robust quality control processes in place to ensure that products meet industry standards and regulatory requirements.

One practical use case showcasing the importance of selecting the right personal care contract manufacturing partner is a skincare brand that saw a significant increase in sales after partnering with a reputable manufacturer known for their high-quality products. By outsourcing their manufacturing needs to this partner, the brand was able to meet consumer demands, maintain product consistency, and ultimately increase their profits.